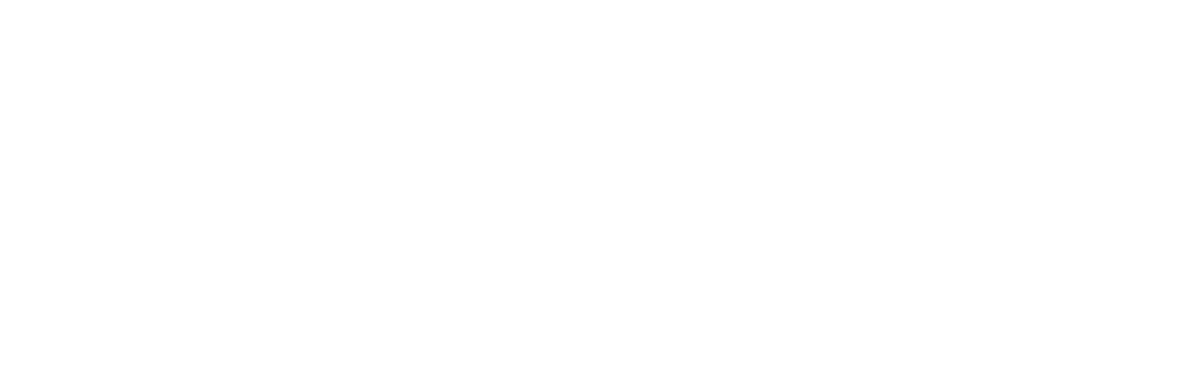

Digital twin supply chain technology is like having a crystal ball for your entire operation — a virtual mirror that lets you poke, prod, and predict what happens before it actually does in the real world. Imagine cloning your warehouse, your trucks, your suppliers, even that finicky assembly line in Vietnam, all into a digital playground where you can run wild experiments without risking a dime or a delay. If you’ve ever lost sleep over a delayed shipment or a surprise shortage, this tech isn’t just cool; it’s your new best friend.

In this deep dive, we’re unpacking everything about digital twin supply chain technology: what it is, why it’s blowing up right now in 2025, how top companies are using it to crush competition, and — crucially — how you can dip your toes in without overhauling your whole setup. We’ll keep it real, conversational, and packed with analogies because, let’s face it, supply chains are complicated enough without the jargon overload.

Understanding the Basics of Digital Twin Supply Chain Technology

So, what exactly is digital twin supply chain technology? Picture this: it’s a virtual replica of your physical supply chain, built from real-time data streaming in from sensors, ERPs, IoT devices, and even social media signals. Unlike a static model or a fancy spreadsheet, this twin lives and breathes — it updates in near real-time, simulating how changes ripple through your network.

Think of it as the video game version of your supply chain. You can “play” scenarios: What if a hurricane hits Florida? What if demand spikes 30% in Europe? Digital twin supply chain technology crunches the numbers using AI, machine learning, and simulation tools to spit out predictions, risks, and optimizations. It’s not sci-fi; it’s here, helping companies dodge bullets they didn’t even see coming.

Why Digital Twin Supply Chain Technology Is a Game-Changer in 2025

Remember the good old days when supply chains were predictable? Yeah, me neither. With climate weirdness, geopolitical drama, and consumer whims flipping faster than TikTok trends, traditional planning feels like using a flip phone in the smartphone era.

Enter digital twin supply chain technology. It’s exploding because data is everywhere now — cheap sensors, cloud computing, and AI make it feasible even for mid-sized players. According to insights from industry leaders, this tech can slash inventory costs by 15%, boost on-time deliveries by 20%, and even cut your carbon footprint by optimizing routes and buffers. Why react to disruptions when you can simulate them weeks ahead?

And hey, if you’re already using tools like predictive analytics for supply chain disruptions, digital twins take it up a notch by not just forecasting issues but virtually testing fixes in real-time.

The Key Components That Make Digital Twin Supply Chain Technology Tick

Data: The Fuel for Your Digital Twin

At its core, digital twin supply chain technology guzzles data like a V8 engine. We’re talking ERP outputs, inventory levels, GPS from trucks, weather APIs, supplier performance histories — even market sentiment from news feeds. The magic happens when this data flows in real-time, often via IoT sensors or blockchain for unbreakable traceability.

AI and Simulation: The Brains Behind the Operation

Once the data’s in, AI algorithms — think machine learning models — analyze it. Simulation software then creates “what-if” scenarios. Want to know if shifting suppliers from China to Mexico saves money? Digital twin supply chain technology runs thousands of simulations in minutes, factoring in tariffs, lead times, and fuel prices.

Visualization and Integration: Making It User-Friendly

No one wants a clunky interface. Modern digital twin supply chain technology platforms offer dashboards that look like sci-fi control rooms — 3D maps, heat maps for bottlenecks, and even VR walkthroughs of virtual warehouses. They integrate seamlessly with existing systems like SAP or Oracle, so you’re not starting from scratch.

Real-World Benefits of Implementing Digital Twin Supply Chain Technology

Boosting Resilience Against Disruptions

Ever had a port strike tank your quarter? Digital twin supply chain technology spots risks early. By modeling end-to-end flows, it predicts bottlenecks and suggests reroutes. Companies using it report recovering from disruptions 50% faster, per recent studies.

Optimizing Costs and Efficiency

Inventory sitting idle? Overpaying for freight? This tech dynamically adjusts buffers and routes. One analogy: it’s like a smart thermostat for your supply chain — always tweaking to save energy (or in this case, dollars). Expect 10-20% reductions in logistics costs alone.

Enhancing Sustainability and Compliance

With ESG pressures mounting, digital twin supply chain technology tracks carbon emissions per shipment or product. It helps you simulate greener alternatives, like electric fleets or recycled materials, without trial-and-error in the real world.

How Top Companies Are Using Digital Twin Supply Chain Technology Today

Microsoft’s Eco-Friendly Overhaul

Tech giant Microsoft leveraged digital twin supply chain technology to bake carbon data into every decision. They swapped wood pallets for sustainable alternatives, slashing emissions by 40% while keeping profits steady. It’s a prime example of how this tech turns green goals into bottom-line wins.

Nestlé’s Agile Demand Juggling

Food behemoth Nestlé built a digital twin to handle volatile demand amid global hiccups. Real-time analytics let them compare scenarios 60% faster, ensuring shelves stay stocked without overproducing. Non-tech users even tweak models via intuitive apps — democratizing data like never before.

A Steel Manufacturer’s Risk Mastery

In the heavy industry, a major steel player used digital twin supply chain technology to simulate 50 plants, 300 warehouses, and 20,000+ SKUs. They spotted risks 12 weeks out, boosting EBITDA by 2 points and trimming inventory 15%. It’s proof this isn’t just for tech firms; it’s for anyone with complex ops.

For more on spotting those risks before they hit, dive into our piece on [predictive analytics for supply chain disruptions].

Step-by-Step Guide to Implementing Digital Twin Supply Chain Technology

Step 1: Assess Your Current Setup

Don’t dive in blind. Audit your data sources — what’s digitized? Where are the gaps? Start small: focus on one pain point, like inventory or transportation.

Step 2: Choose the Right Platform

Options abound in 2025. Check out Coupa’s Supply Chain Design, which powers twins with AI for scenario testing. Or AnyLogistix, great for simulation-heavy users. Look for scalability and easy integration.

Step 3: Build and Integrate Data Flows

Hook up your ERP, IoT, and external feeds. Use APIs for seamless syncing. Pro tip: Start with synthetic data if real-time’s spotty — it gets you testing fast.

Step 4: Train Your Team and Iterate

This isn’t set-it-and-forget-it. Run workshops, use agile methods, and refine models based on real outcomes. Within months, you’ll see ROI.

Step 5: Scale and Optimize

Once it’s humming, expand to full end-to-end. Pair with AI for prescriptive advice — not just “what might happen,” but “do this now.”

Challenges You’ll Face with Digital Twin Supply Chain Technology (And How to Beat Them)

No tech’s perfect. Data silos can cripple your twin — solution: invest in middleware for clean integration. Training hurdles? Opt for user-friendly platforms with guided onboarding. Costs? Cloud-based options start low, with ROI kicking in quick from avoided disruptions.

Mindset shifts are big too. Siloed teams must collaborate; institutional “gut feels” give way to data. But conquer these, and digital twin supply chain technology becomes your unfair advantage.

The Future of Digital Twin Supply Chain Technology: What’s Next?

By 2030, expect digital twins to be standard, with generative AI writing contingency plans on the fly. We’ll see blockchain for ultra-secure data sharing, and metaverse-style twins for collaborative planning across borders. The market’s booming — projected to hit $150 billion — as volatility stays high.

Imagine twins predicting not just disruptions but market shifts, auto-adjusting contracts, or even designing new products virtually. It’s evolving from reactive tool to proactive powerhouse.

Getting Started with Digital Twin Supply Chain Technology Tomorrow

Ready to clone your chain? Pick a pilot: say, your distribution network. Grab a free trial from a vendor like Resilinc for risk-focused twins. Measure wins: fewer stockouts, lower costs. Scale from there.

Remember, this pairs perfectly with related tech. For instance, integrating [predictive analytics for supply chain disruptions] amps up your forecasting game.

Conclusion: Embrace the Twin or Get Left Behind

Digital twin supply chain technology isn’t a fad — it’s the evolution of resilient, efficient operations in a world that won’t slow down. From slashing costs and emissions to outsmarting crises, it empowers you to not just survive but thrive. The tools are accessible, the benefits proven, and the future bright. So, why wait for the next disruption to hit? Build your twin today, and watch your supply chain transform from fragile to unbreakable.

Your competitors are probably already simulating their edge — time to join the game?

FAQs About Digital Twin Supply Chain Technology

1. How does digital twin supply chain technology differ from traditional simulation software?

Traditional sims are static and manual; digital twin supply chain technology uses real-time data and AI for dynamic, predictive modeling that evolves with your operations.

2. Is digital twin supply chain technology only for large enterprises?

Nope! Cloud platforms make it affordable for SMBs too, with quick ROI from optimized inventory and reduced risks.

3. Can digital twin supply chain technology help with sustainability?

Absolutely — it models emissions, optimizes routes for lower carbon, and simulates eco-friendly changes without real-world trials.

4. How long does it take to see results from digital twin supply chain technology?

Pilots can deliver insights in 3-6 months, with full implementations yielding 10-20% efficiency gains within a year.

5. Does digital twin supply chain technology integrate with existing systems?

Yes, most platforms hook into ERPs like SAP via APIs, making adoption smoother than you think.